Why Understanding Dye Application is Essential for Successful Textile Production

The textile industry is a cornerstone of the global economy, accounting for approximately $1.5 trillion in revenue annually. Within this vast industry, dye application plays a critical role in determining the final quality and value of textile products. According to a report by Smithers Pira, a leading authority in the printing and dyeing sector, nearly 70% of the environmental impact of textiles can be attributed to the dyeing process. As such, understanding the nuances of dye application is vital not only for achieving vibrant colors but also for ensuring sustainability in production practices.

Experts in the field emphasize the significance of mastering dye application techniques. Dr. Emily Chen, a renowned textile scientist at the International Textile Research Institute, states, "Effective dye application is essential for producing textiles that meet both aesthetic and environmental standards." Companies that prioritize innovative dyeing methods and sustainable practices can not only enhance their product quality but also appeal to an increasingly eco-conscious consumer base. As the industry continues to evolve, a deep understanding of dye application will become indispensable in navigating the challenges and opportunities within textile production.

Importance of Dye Application in Textile Industry

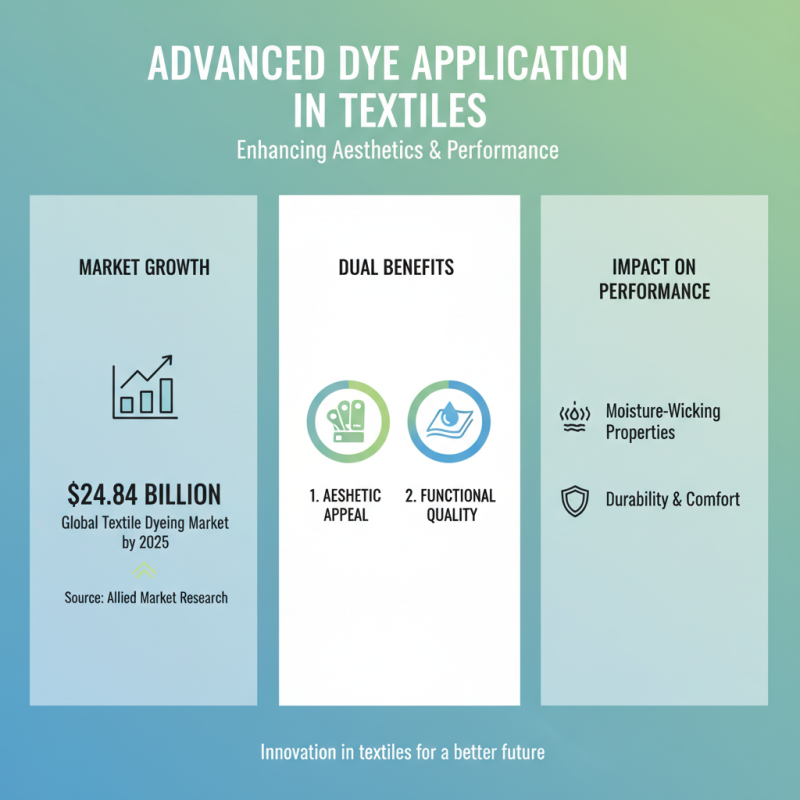

In the textile industry, dye application plays a pivotal role in ensuring both the aesthetic and functional qualities of fabric. According to a report by Allied Market Research, the global textile dyeing market is projected to reach $24.84 billion by 2025, highlighting the growing significance of advanced dye application techniques. Proper dye application not only enhances visual appeal but also impacts how textiles perform under various conditions. For example, the right dyeing process can improve moisture-wicking properties, ensuring that garments are comfortable for the wearer.

Furthermore, understanding dye application is crucial for sustainability in textile production. The OECD reports that textile dyeing is responsible for nearly 20% of global water pollution. By implementing eco-friendly dyeing methods—such asdigital printing and natural dyes—manufacturers can significantly mitigate their environmental impact. The shift towards sustainable dye application not only meets rising consumer demand for eco-conscious products but also drives innovation and efficiency, ultimately contributing to the long-term viability of the textile industry.

Types of Dyes Used in Textile Production

The selection of dyes is a critical aspect of textile production, with various types available that cater to different fabric compositions and desired outcomes. Among the most commonly used dyes are reactive dyes, which form strong covalent bonds with the textile fibers. This type of dye is favored for its vibrant colors and excellent washfastness, making it ideal for cotton and other cellulose fibers. Another significant category is acid dyes, which are primarily used on protein fibers such as wool and silk. Acid dyes offer a wide range of shades and brilliant colors, but their application requires careful control of pH levels to achieve optimal results.

Additionally, direct dyes and disperse dyes play an important role in the dyeing process. Direct dyes are known for their ease of application on cellulosic fibers and can produce bright colors with good washfastness. In contrast, disperse dyes are primarily used for synthetic fibers like polyester and nylon. They require a special dyeing process that often involves high temperatures to ensure that the dye penetrates the fibers adequately. Each type of dye presents unique advantages and challenges, and understanding these differences is essential for textile manufacturers aiming to produce high-quality, durable products in a competitive market.

Factors Influencing Dyeing Process Efficiency

The efficiency of the dyeing process is influenced by several critical factors that play a significant role in the overall success of textile production. First and foremost, the choice of dyeing methods—such as batch dyeing or continuous dyeing—can significantly affect the time and resources required for color application. Each method presents unique advantages and challenges, depending on the type of fabric and dye used. For instance, batch dyeing may provide greater color consistency, while continuous dyeing is often faster and more suitable for large-scale operations.

Another vital consideration is the quality of the water used during the dyeing process. Water quality can alter dye uptake, leading to variations in color depth and consistency. Hard water, which contains high levels of minerals, can interfere with the dye's ability to bond with the fabric, resulting in uneven coloration. Additionally, the temperature and pH levels of the dyeing solution also significantly impact the efficiency of the dyeing process. The optimal conditions for each dye vary, and maintaining the right parameters ensures maximum dye fixation and reduces the amount of dye runoff, thereby improving cost-effectiveness and minimizing environmental impact.

Techniques for Effective Dye Application

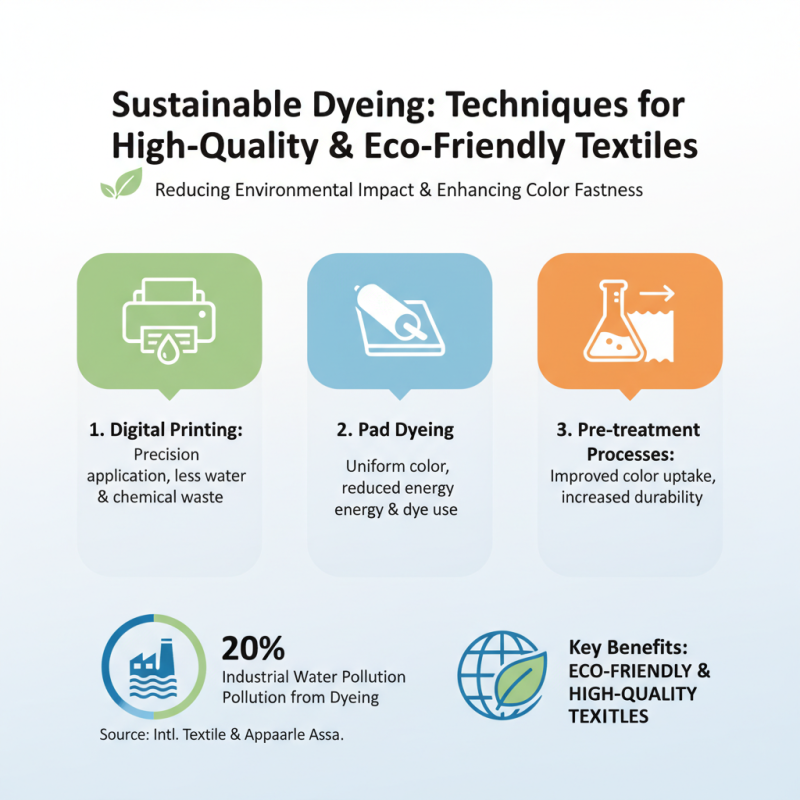

Understanding the techniques for effective dye application is crucial to achieving high-quality textiles. According to a report by the International Textile and Apparel Association, approximately 20% of the world's industrial water pollution comes from dyeing processes. This emphasizes the importance of optimizing dye application methods to not only enhance color fastness but also reduce environmental impact. Techniques such as digital printing, pad dyeing, and the use of pre-treatment processes allow manufacturers to improve efficiency and minimize waste.

Tips for successful dye application include careful fabric preparation and selecting the appropriate dye type for the fiber content. For instance, reactive dyes are ideal for cotton, as they bond well with the fiber, resulting in vibrant colors and durability. Additionally, controlling the dyeing temperature and pH levels can significantly affect the final outcome, as these factors influence the rate of dye absorption and the uniformity of the color.

Employing sustainable practices in dye application is gaining traction, as companies seek to meet consumer demand for environmentally friendly products. Techniques such as low-impact dyes and closed-loop water systems can help reduce water usage and chemical discharge. Staying updated on industry reports, such as those from the World Sustainable Textile Conference, can provide insights into innovative methods that align with sustainability goals while ensuring quality in textile production.

Impact of Dyeing on Fabric Quality and Sustainability

The dyeing process is a critical element in textile production, significantly impacting the quality and sustainability of fabrics. Various dyeing techniques can influence the durability, colorfastness, and overall functionality of textile products. High-quality dyeing can enhance the aesthetic appeal of fabrics, making them more attractive to consumers. However, poor dyeing practices can lead to issues such as fading, bleeding, and even fabric degradation over time, ultimately affecting customer satisfaction and brand reputation.

When considering sustainability, it's essential to utilize eco-friendly dyes and water-efficient dyeing methods. These practices not only minimize the environmental impact but also improve fabric qualities. For instance, opting for natural dyes derived from plants or minerals can reduce the carbon footprint associated with synthetic dyes. Implementing advanced dyeing technologies that recycle water and minimize waste can further support sustainable textile production.

**Tips**:

1. Always choose dyes that have low environmental impact and are free from harmful chemicals to enhance sustainability.

2. Regularly evaluate dye application methods to ensure they align with both quality standards and environmental regulations.

3. Educate your team on best practices in dye application to maintain consistency and quality in textile production.

Impact of Dyeing on Fabric Quality and Sustainability

Related Posts

-

How to Achieve Sustainability in the Textile Industry: Key Strategies and Practices

-

Best Spray for Textile Protection and Stain Resistance in 2023

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

Top 10 Insights into the Textile Dyeing Process You Need to Know

-

Understanding the dyeing process for the top fabrics of 2025

-

2025 How to Master the Textile Finishing Process for Optimal Results