Why the Textile Finishing Process is Essential for High Quality Fabrics

The textile finishing process plays a crucial role in determining the quality and performance of fabrics. As industry expert Dr. Emily Hartman observes, "The finishing process is where the fabric truly comes to life, transforming raw textiles into high-quality materials that meet consumer demands." In an ever-evolving market that places increasing emphasis on standards and sustainability, the importance of a meticulous finishing process cannot be overstated.

This process encompasses various treatments and techniques designed to enhance the aesthetics, functionality, and durability of textiles. From improving water repellency to increasing softness, the textile finishing process ensures that fabrics not only look appealing but also perform exceptionally well in everyday use. The integration of advanced technologies and environmentally friendly practices within this phase of production further emphasizes its significance in delivering high-quality fabrics that resonate with modern consumers' preferences.

As we delve into the intricacies of the textile finishing process, we recognize its foundational role in the textile industry. By understanding the various techniques involved and their impact on fabric quality, stakeholders can appreciate how essential finishing truly is for crafting superior textiles that stand the test of time.

Importance of Textile Finishing in Enhancing Fabric Quality

The textile finishing process plays a crucial role in enhancing fabric quality by imparting desirable characteristics that elevate the overall performance and aesthetic appeal of textiles. This final stage of textile production involves various treatments that improve the fabric's texture, durability, and functionality. Through methods such as chemical treatments, heat application, and surface modifications, fabrics can achieve increased resistance to wrinkling, staining, and fading, ensuring longevity and satisfaction for consumers.

Moreover, textile finishing enhances the sensory qualities of fabrics, making them more pleasant to touch and visually appealing. Finishing processes such as softening treatments and dyeing can transform a rough and bland fabric into one that is not only comfortable to wear but also vibrant in color. The importance of these enhancements cannot be overstated; they directly affect consumer preferences and marketability. High-quality finishes cater to specific applications, whether it be for fashion apparel, home textiles, or functional outdoor gear, thus broadening the potential uses of various fabric types.

Overview of Common Textile Finishing Techniques and Their Effects

The textile finishing process is a crucial step in enhancing the quality and performance of fabrics. Various techniques are commonly employed to achieve specific attributes that enhance the user experience. One popular method is chemical finishing, which involves the application of chemical agents to impart features such as water repellency, soil resistance, or flame retardance. This approach not only improves the functionality of fabrics but also extends their lifespan, making them ideal for a range of applications from everyday clothing to specialized industrial materials.

Another widely used finishing technique is mechanical finishing, which includes processes like calendaring, shearing, and raising. Calendaring compresses the fabric under heated rollers to achieve a smooth, glossy surface, while shearing involves cutting the surface fibers to create a softer texture. Raising, on the other hand, lifts the fibers to enhance warmth and provide a distinctive tactile quality. Each of these methods contributes to the aesthetic appeal and tactile sensation of the fabric, ensuring that consumers enjoy not only the look but also the feel of high-quality textiles. Through these finishing techniques, manufacturers can create fabrics that are not only visually stunning but also meet the specific needs of consumers in terms of comfort and durability.

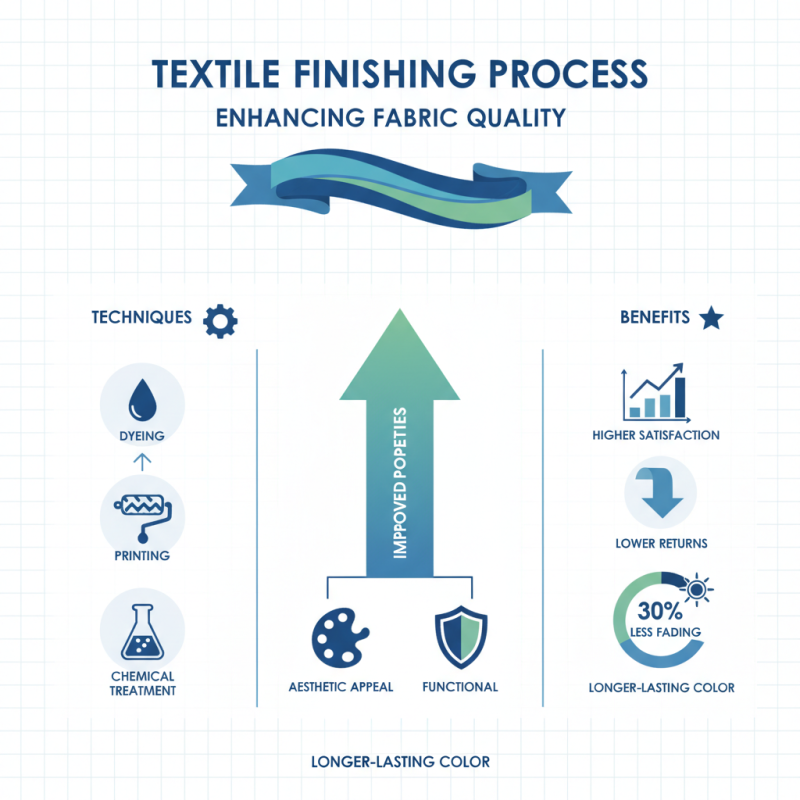

Statistical Insights: Quality Improvement Through Finishing Processes

The textile finishing process plays a critical role in enhancing the quality of fabrics. By implementing various techniques such as dyeing, printing, and chemical treatment, manufacturers can significantly improve the aesthetic appeal and functional properties of textiles. Statistical insights reveal that fabrics subjected to thorough finishing processes exhibit higher rates of customer satisfaction and lower returns due to defects. For instance, studies have shown that finished textiles can reduce the risk of fading by up to 30%, ensuring longer-lasting color retention.

Moreover, the impact of finishing on performance characteristics cannot be overlooked. Fabrics that undergo specialized finishing treatments are often more resistant to wrinkles, stains, and wear, which translates to greater durability. A recent analysis indicated that finished textiles outperform their unfinished counterparts by over 25% in terms of tensile strength and overall lifespan. These enhancements can lead to increased consumer trust and brand loyalty, highlighting the importance of investing in quality finishing processes to achieve superior textile products.

Sustainability in Textile Finishing: Balancing Quality and Environmental Impact

The textile finishing process is often seen as the final stage in fabric production, significantly influencing the quality, texture, and performance of textiles. However, the environmental impact of traditional finishing methods raises critical questions about sustainability. As the fashion and textile industries face increasing scrutiny over their environmental footprints, incorporating sustainable practices in textile finishing has become essential. By utilizing eco-friendly chemicals, water-efficient processes, and renewable energy sources, manufacturers can reduce waste and energy consumption, creating fabrics that not only meet high-quality standards but also align with environmental goals.

Balancing the dual imperatives of quality and sustainability requires innovative techniques and a commitment to responsible sourcing. Technologies such as digital printing and enzyme-based treatments have emerged as effective alternatives to conventional methods, minimizing harmful runoff and reducing the use of toxic substances. Moreover, implementing circular economy principles in textile finishing can facilitate the recycling and reuse of materials, lowering the overall environmental burden. By focusing on sustainable practices, the textile industry can enhance fabric quality while contributing to a healthier planet, demonstrating that it is possible to achieve excellence without compromising ecological integrity.

Future Trends in Textile Finishing: Innovations Driving Quality Fabrics

In the realm of textile production, advancements in finishing processes are pivotal in enhancing fabric quality and functionality. Recent industry reports highlight that the global textile finishing market is projected to grow at a CAGR of 5.4% from 2021 to 2026, driven by innovations that cater to evolving consumer demands for sustainability and performance. Innovative treatments such as nanotechnology and 3D printing are revolutionizing the way fabrics are finished, allowing for the incorporation of features such as water resistance, stain repellency, and antibacterial properties, which significantly elevate the overall quality of textiles.

Moreover, the increasing emphasis on eco-friendly practices has ushered in the adoption of sustainable dyeing and finishing techniques. According to a report by the Textile Exchange, there is a growing trend towards organic and recycled materials, with over 30% of global textile production now incorporating some form of sustainable practice. Techniques such as digital printing and laser finishing not only minimize water and chemical use but also enhance the visual appeal and durability of fabrics. These innovations point to a future where high-quality textiles are not only defined by their aesthetic and tactile characteristics but also by their environmental impact, aligning with the broader trends of corporate responsibility and consumer awareness in today’s market.

Related Posts

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

Understanding the dyeing process for the top fabrics of 2025

-

How to Navigate the Dyeing Finishing Process for Optimal Fabric Results

-

How to Achieve Sustainability in the Textile Industry for a Greener Future

-

Why is the Dyeing Process Essential in the Textile Industry for Quality and Sustainability