How to Achieve Sustainability in the Textile Industry for a Greener Future

Sustainability in the textile industry has become an urgent topic as the world grapples with climate change and resource depletion. Experts in the field emphasize the necessity of transforming traditional practices to foster a more environmentally friendly approach. Dr. Jane Smith, a renowned environmental scientist specializing in sustainable textiles, asserts, "For the textile industry, embracing sustainability is not just a trend; it’s a crucial milestone towards a more responsible future." This perspective highlights the critical need for change within an industry that has long been associated with excessive waste and pollution.

As we seek to achieve sustainability in the textile industry, it is vital to consider the entire supply chain, from raw material sourcing to production and distribution. Implementing innovative practices, such as using organic fibers, reducing water consumption, and recycling materials, can significantly lessen the environmental impact of textile production. Industry stakeholders, including manufacturers, designers, and consumers, must collaborate to forge a new path that prioritizes ecological balance while still meeting the demands of a growing population.

The journey toward a greener future in textiles requires unwavering commitment and creativity. By embracing sustainable practices, the industry can not only mitigate its negative impacts on the environment but also enhance its resilience and adaptability in the face of future challenges. Thus, the push for sustainability in the textile industry is not merely about compliance; it represents an opportunity for transformation and progress.

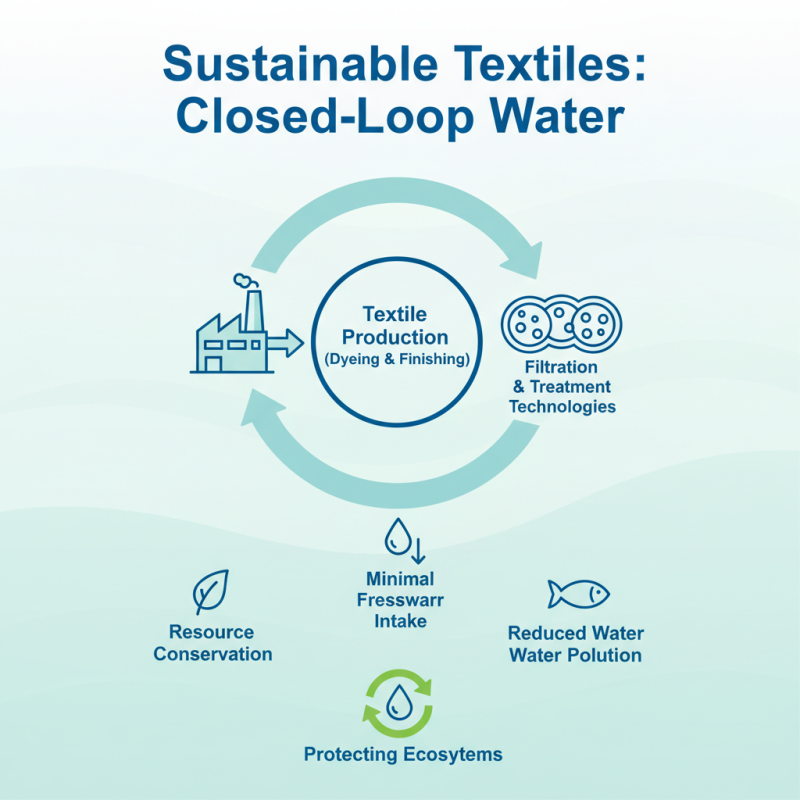

Strategies for Reducing Water Consumption in Textile Production

Reducing water consumption in textile production is crucial for achieving sustainability in the industry. One effective strategy is the adoption of closed-loop water systems, which recycle water used in processes like dyeing and finishing. By implementing filtration and treatment technologies, manufacturers can minimize freshwater intake while ensuring water quality remains suitable for reuse. This not only conserves resources but also reduces the risk of water pollution, helping to protect local ecosystems.

Another approach is to optimize dyeing processes through the use of waterless dyeing technologies. These innovative methods, such as using supercritical CO2 or digital printing techniques, drastically cut down on the water required for traditional dyeing. Additionally, educating workers on best practices for water management is essential. Training programs can help instill a culture of sustainability within the workforce, encouraging everyone to identify and reduce water waste at every stage of production. These collective efforts lead to significant improvements in water efficiency, contributing to a greener future for the textile industry.

Innovative Materials: Exploring Biodegradable and Recycled Fabrics

The textile industry is at a pivotal crossroads, where the need for sustainability is becoming increasingly urgent. Innovative materials like biodegradable and recycled fabrics offer promising solutions to reduce the environmental impact of textile production. Biodegradable fabrics, made from natural fibers or biodegradable polymers, break down more easily in the environment, thereby decreasing landfill waste. On the other hand, recycled fabrics, which can be sourced from post-consumer waste, not only conserve resources but also significantly lower energy consumption during production.

Tips: When shopping for textiles, look for labels indicating recycled or biodegradable materials. Choosing garments made from these materials can support sustainable practices and help decrease the overall demand for virgin resources. Additionally, consider the life cycle of a product and aim for long-lasting items that won’t need to be replaced frequently.

The transition to these sustainable materials is not just beneficial for the environment but also opens doors for innovation in design and functionality. Brands that incorporate biodegradable and recycled fabrics often find that they can engage eco-conscious consumers more effectively. By embracing these materials, the textile industry can lead the way toward a greener future while promoting a circular economy where products are designed with their entire lifecycle in mind.

Tips: Educate yourself about the different types of sustainable materials available. Explore fabric options such as organic cotton, hemp, or Tencel, which may offer both performance and sustainability. Engaging with brands that prioritize these materials can encourage further shifts in the industry towards more responsible practices.

Implementing Circular Economy Principles in the Textile Supply Chain

Implementing circular economy principles in the textile supply chain is essential for fostering sustainability within the industry. The traditional linear model of production—where resources are extracted, used, and discarded—leads to excessive waste and environmental degradation. In contrast, circular economy emphasizes a regenerative approach that keeps products and materials in use for as long as possible. This can be achieved by designing textiles for longevity, promoting repair and reuse, and utilizing innovative recycling technologies that convert textile waste back into raw materials.

A collaborative effort among stakeholders is vital to successfully integrate these principles into existing supply chains. Manufacturers, retailers, and consumers must work together to create a system where fabric scraps and end-of-life garments are seen not as waste, but as valuable resources. Implementation of take-back schemes and recycling programs can encourage consumers to return their used clothing, thereby reducing landfill contributions. Additionally, investing in processes that enhance resource efficiency, such as closed-loop production techniques, can significantly lower the environmental footprint of textile manufacturing.

Furthermore, education and awareness play a critical role in transitioning to a circular economy. Stakeholders must be informed about the environmental impacts of textile waste and the benefits of circular practices. By fostering a culture of sustainability, the industry can encourage consumers to make conscious choices that support eco-friendly practices. In this way, the textile industry can pave the way for a greener future, ensuring that the materials used today do not hinder the well-being of future generations.

The Role of Technology in Enhancing Sustainable Textile Practices

The textile industry is a significant contributor to environmental degradation, with studies indicating that it accounts for approximately 10% of global carbon emissions. Technology plays a crucial role in transforming traditional practices into sustainable alternatives. Innovations such as digital textile printing significantly reduce water consumption by up to 90% compared to conventional dyeing methods. Moreover, automated cutting machines are optimizing fabric usage, thereby minimizing waste in production processes.

Additionally, advancements in recycling technologies are enabling the efficient repurposing of textile waste. According to the Ellen MacArthur Foundation, only 1% of the material used to produce clothing is recycled into new garments, but technologies such as chemical recycling can break down fibers and regenerate them for production. This not only mitigates the demand for virgin materials but also curbs pollution associated with textile disposal. Embracing these technologies can markedly enhance sustainability in the textile sector and contribute to a greener future.

Measuring Carbon Footprint: Key Metrics for Textile Industry Sustainability

Measuring the carbon footprint is an essential step towards achieving sustainability in the textile industry. The industry's impact on the environment is significant, with processes such as manufacturing, transportation, and disposal contributing to greenhouse gas emissions. Key metrics for assessing the carbon footprint include direct emissions from manufacturing facilities, energy consumption, and waste management practices. By establishing a comprehensive carbon accounting framework, textile companies can identify their primary sources of emissions and implement targeted strategies to reduce their environmental impact.

To facilitate effective measurement, the textile industry can adopt standardized metrics like the Greenhouse Gas Protocol or ISO 14064. These frameworks provide guidelines for quantifying emissions across different stages of the supply chain—from raw material sourcing to product end-of-life. Additionally, integrating life cycle assessments (LCAs) can offer deeper insights into the environmental impacts associated with various textile products, enabling companies to make informed decisions about materials and processes that align with sustainability goals. By prioritizing transparency in their carbon footprint measurements, textile manufacturers can foster a culture of accountability and innovation geared toward a greener future.

Carbon Footprint Metrics in the Textile Industry

This chart illustrates the carbon footprint of various stages in the textile production process, highlighting the significance of sustainability efforts in the industry. Data reflects average emissions per stage measured in kilograms of CO2 equivalent.

Related Posts

-

How to Achieve Sustainability in the Textile Industry: Key Strategies and Practices

-

Best Spray for Textile Protection and Stain Resistance in 2023

-

Why is the Dyeing Process Essential in the Textile Industry for Quality and Sustainability

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

Top 10 Insights into the Textile Dyeing Process You Need to Know

-

2025 How to Master the Textile Finishing Process for Optimal Results