How to Optimize the Textile Industry Dyeing Process for Better Results

In the competitive realm of the textile industry, optimizing the dyeing process is crucial. Industry expert Dr. Emily Chang states, “Enhancing dyeing efficiency can significantly improve fabric quality.” Her insight underscores the importance of refining methods to produce vibrant and durable textiles.

The textile industry dyeing process has traditionally faced challenges like inconsistent color matching and environmental concerns. Innovations in technology and sustainable practices can address these issues. For example, using digital dyeing techniques can reduce water usage and waste. However, many companies still rely on outdated practices, raising questions about their commitment to sustainability.

There are opportunities for improvement. Streamlining workflows and investing in employee training can elevate the dyeing process. Yet, even with advancements, the risk of color inaccuracies persists. The industry must continually evaluate and adapt to ensure excellence in dyeing processes, leading to better results and a greener footprint.

Optimizing Water Usage in Textile Dyeing to Achieve Eco-friendly Results

Water is a precious resource in the textile dyeing process. Traditional methods often waste significant amounts of it. This inefficiency leads to increased costs and environmental damage. By optimizing water usage, the industry can promote sustainability. Recycling and reusing water can drastically reduce consumption. Simple technologies can help treat and filter water.

Implementing new dyeing techniques also aids in conservation. For instance, digital printing or low-water dyeing methods can cut down on usage. Despite these advancements, many facilities still rely on outdated processes. Training and awareness are crucial here. Workers need to understand the importance of each drop.

Moreover, monitoring and measuring water usage can identify areas for improvement. Yet, many businesses overlook this step. Regular audits could reveal leaks or inefficiencies. In striving for eco-friendly results, the industry must confront these challenges. Less water means a healthier planet, but this requires commitment and innovation from all players.

Optimizing Water Usage in Textile Dyeing

This chart illustrates the water usage in different dyeing processes, highlighting the importance of optimizing water consumption for eco-friendly results in the textile industry.

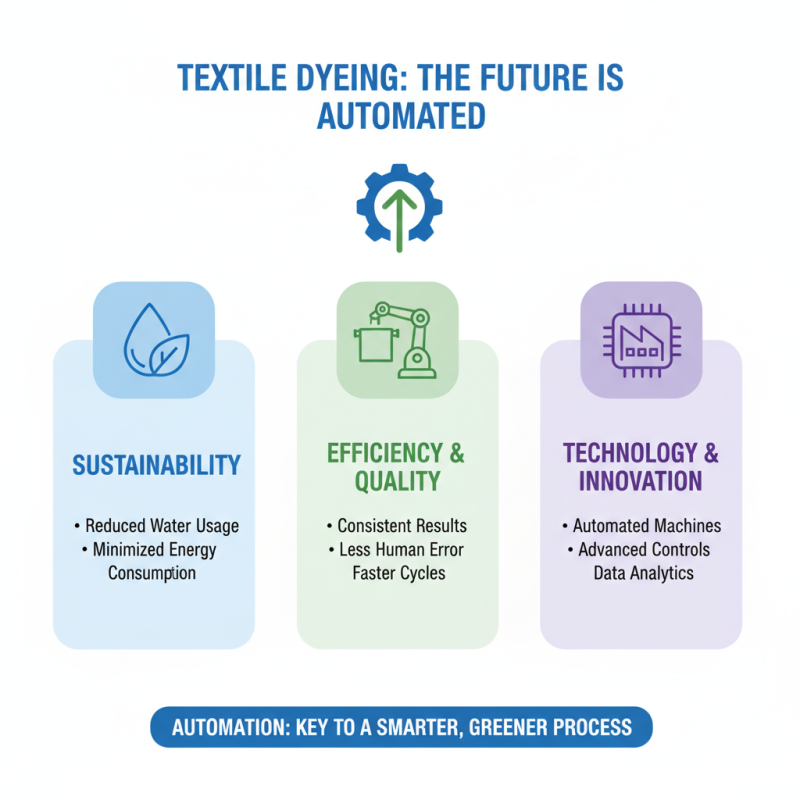

Implementing Advanced Technologies for Dyeing Process Efficiency

The textile dyeing process faces numerous challenges. Advanced technologies can address these issues effectively. Automation is key to improving efficiency. Automated dyeing machines can reduce human error and provide consistent results. They can also minimize water and energy usage, which is vital for sustainability.

Another technology worth exploring is digital printing. This method offers precision and customization. Brands can reduce dye waste and meet specific color requirements. However, the transition to digital printing still poses challenges. The initial investment can be high, and some employees may require retraining.

Data analytics plays a critical role in optimizing the dyeing process. By analyzing data, professionals can identify patterns and predict outcomes. This information helps in making informed decisions. Yet, many businesses struggle to implement these systems fully. There is a learning curve, and some may resist change. A balance between technology and traditional methods might be necessary for a smooth transition.

Analyzing Dyeing Chemicals: Choosing Eco-friendly and High-Efficiency Options

Choosing the right dyeing chemicals is crucial for the textile industry. Eco-friendly options are gaining popularity for their reduced environmental impact. Natural dyes often come from plants, providing a unique aesthetic. However, they may not always have the same vibrancy or longevity as synthetic dyes. This inconsistency can be a challenge for manufacturers seeking high-quality results.

High-efficiency dyes are designed to maximize color yield while minimizing waste. They can save water and energy in the dyeing process, which is vital for sustainability. Yet, the search for the ideal chemical mix is ongoing. Experts must balance efficiency with ecological concerns. Some solutions may not work well for all materials. Color retention may be less than expected.

Furthermore, education on dye chemicals is essential. Many workers in the industry are unaware of eco-friendly alternatives. Training can bridge this gap, fostering an environmentally conscious workforce. Adapting to these changes takes time and effort. Yet, the potential benefits are significant, leading to better results for both the business and the planet.

How to Optimize the Textile Industry Dyeing Process for Better Results

| Dyeing Chemical | Type | Eco-Friendliness Rating | Efficiency Rating | Cost per kg |

|---|---|---|---|---|

| Reactive Dyes | Synthetic | 4/5 | 85% | $15 |

| Natural Plant Dyes | Natural | 5/5 | 70% | $25 |

| Acid Dyes | Synthetic | 3/5 | 80% | $10 |

| Disperse Dyes | Synthetic | 2/5 | 75% | $8 |

| Vat Dyes | Synthetic | 4/5 | 90% | $20 |

Improving Color Fastness: Techniques for Enhanced Dye Stability

Improving color fastness in the textile dyeing process is crucial. It prevents colors from fading over time. Many factors influence dye stability. The choice of dye is essential. Some dyes are more vibrant but less stable. Understanding the chemical properties of dyes can help optimize results.

Water quality significantly affects dye adherence. High mineral concentrations can alter dye performance. Conducting tests with different water sources can help identify the best options. Additionally, pH levels play a crucial role in dye absorption. A balanced pH can improve the vibrancy of colors.

Pre-treatment methods are another area for improvement. Properly preparing the fabric enhances dye absorption. Some techniques require careful execution. Overlooking this step can lead to unsatisfactory results. Regularly reviewing processes and experimenting with new methods helps in achieving better outcomes. It's essential to embrace a trial-and-error approach in pursuit of perfection.

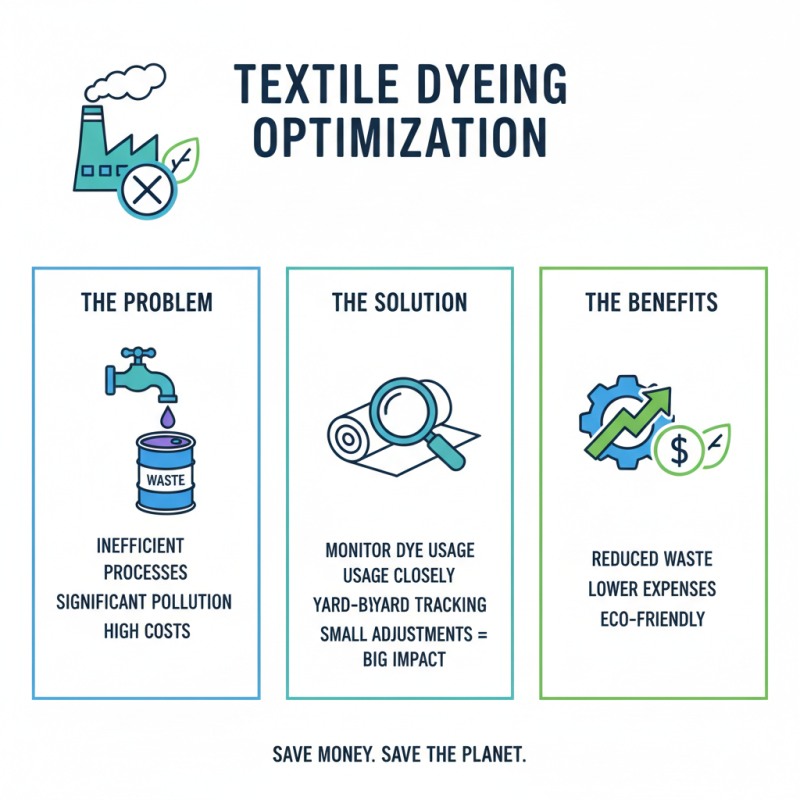

Monitoring and Reducing Waste in the Dyeing Process through Best Practices

The dyeing process in the textile industry is often inefficient. Waste can be significant, affecting both costs and the environment. Monitoring dye usage closely is critical. For every yard of fabric, excess dye can lead to pollution. Small adjustments can make a big impact.

Implementing best practices is essential. Regularly calibrating dyeing machines can reduce errors. Training staff on accurate dye measurement also helps. Good communication among team members can lead to fewer mistakes. There are still instances where dyes aren’t utilized fully, so continual reflection is necessary.

Wastewater treatment is another aspect needing attention. Some processes generate excessive waste, which is not always properly handled. Innovative solutions require time and brainstorming. The industry must keep questioning its practices to improve efficiency and minimize waste. Progress is needed, but achieving perfection seems a distant goal.

Related Posts

-

Why Understanding Dye Application is Essential for Successful Textile Production

-

Why is the Dyeing Process Essential in the Textile Industry for Quality and Sustainability

-

How to Navigate the Dyeing Finishing Process for Optimal Fabric Results

-

How to Achieve Sustainability in the Textile Industry for a Greener Future

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

How to Achieve Sustainability in the Textile Industry: Key Strategies and Practices