How to Optimize the Dyeing Process in the Textile Industry for Better Results

The textile industry dyeing process is a critical aspect of textile manufacturing, contributing significantly to the aesthetic appeal and marketability of finished products. According to a report by the World Bank, the textile and clothing sector accounts for approximately 7% of global merchandise trade, underscoring the importance of efficiency in production processes, including dyeing. With the growing demand for sustainable practices, optimizing the dyeing process not only enhances productivity but also minimizes environmental impacts, addressing the concerns raised by the Sustainable Apparel Coalition, which emphasizes the need for eco-friendly manufacturing methods.

Moreover, data from the International Textile Manufacturers Federation indicates that the dyeing process can account for up to 20% of the total production costs in the textile industry. Thus, improving the efficiency and effectiveness of dyeing operations is essential for reducing costs and increasing competitiveness. Implementing advanced technologies, such as digital dyeing and automated processes, can lead to improved dye uptake and reduced water usage, aligning with global sustainability goals. By focusing on optimization strategies, industry players can ensure superior quality and consistency in their products while also adhering to regulatory standards and consumer expectations for environmentally responsible manufacturing.

Understanding the Importance of Dyeing Optimization in Textiles

Dyeing optimization plays a crucial role in the textile industry, as it directly affects the quality and efficiency of the final product. Properly optimized dyeing processes can significantly improve color consistency, fastness, and overall fabric performance. The importance of this optimization cannot be overstated; it not only enhances the aesthetic appeal of textiles but also reduces waste of resources such as water, chemicals, and energy.

By maximizing the efficiency of dyeing operations, manufacturers can achieve better sustainability practices and improve their overall environmental impact.

Furthermore, understanding the various factors that influence the dyeing process—such as temperature, pH levels, and dye concentrations—can lead to better decision-making during fabric production. Investing in advanced dyeing technologies and methods can also facilitate these optimizations. Training staff on the significance of monitoring and controlling these parameters ensures that dyeing processes are consistently executed to meet high quality standards. Ultimately, effective dyeing optimization is essential for maintaining competitive advantage in the textile market, ensuring customer satisfaction, and fostering innovative practices within the industry.

Key Factors Affecting the Dyeing Process Efficiency

The efficiency of the dyeing process in the textile industry is influenced by several key factors that can significantly improve final results. One major factor is the quality of dyestuffs used; selecting high-quality dyes that are appropriate for the specific fabric type can enhance color fastness and vibrancy. Moreover, the preparation of the fabric, including pre-treatment steps like scouring and bleaching, is crucial to ensure that the dye is absorbed evenly and efficiently.

Tips: It is essential to conduct thorough testing before large-scale dyeing. Sampling various color options and dye formulations can help identify the best combination for achieving desired outcomes. Additionally, keeping track of dyeing variables such as temperature, pH levels, and dye concentrations can lead to more consistent results.

Another critical factor affecting dyeing efficiency is the equipment and technology employed in the process. Upgrading to modern dyeing machines equipped with precise control systems can minimize waste and maximize accuracy in the application of dyes. Implementing automation and real-time monitoring systems not only optimizes the process but also reduces human error, leading to improved overall quality.

Tips: Regular maintenance of dyeing equipment is vital for sustained efficiency. Scheduled servicing can prevent breakdowns and ensure consistent performance, ultimately enhancing productivity in the dyeing process.

Methods to Enhance Color Fastness and Quality in Dyeing

Enhancing color fastness and quality in the dyeing process of textiles requires a multifaceted approach that combines effective techniques and careful consideration of materials. One critical method involves optimizing the use of dyeing auxiliaries, which can significantly improve the absorption of dyes into fibers. By selecting the right combination of chemicals, manufacturers can promote better bonding between the dye molecules and the fabric, increasing the longevity and vibrancy of colors. Additionally, adjusting dyeing conditions such as temperature, time, and pH levels can lead to improved results. For instance, precise control over these variables ensures that dyes penetrate deeply and uniformly, reducing the risk of uneven coloration.

Another key aspect is the pre-treatment and after-treatment processes of fabrics. Proper pre-treatment, which may include scouring and bleaching, prepares the fibers to accept dyes more effectively. Meanwhile, after-treatment techniques, such as fixing agents and softeners, can enhance color fastness, preventing fading and bleeding when the fabric is washed or exposed to sunlight. Regular testing and quality control measures during and after dyeing are also crucial. By conducting tests for colorfastness against different conditions, textile producers can ensure their products maintain the desired aesthetic and functional qualities over time. This comprehensive approach ultimately leads to higher quality textiles that meet the growing demands for durability and color integrity in the market.

Innovative Technologies for Streamlining the Dyeing Process

Innovative technologies are revolutionizing the dyeing process in the textile industry, leading to enhanced efficiency and sustainability. One of the most significant advancements is the adoption of digital dyeing techniques. This technology allows for precise color application, reducing the amount of dye and water used while minimizing waste. Digital dyeing methods enable manufacturers to achieve high-quality results with quicker turnaround times, making it easier to respond to fast-changing fashion trends. Additionally, this technology facilitates intricate designs that would be challenging to produce using traditional methods, opening up new creative possibilities for designers.

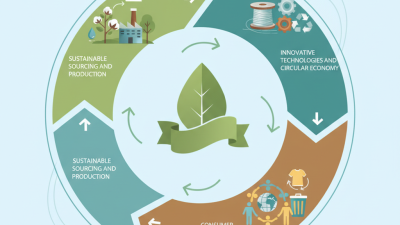

Another promising development is the application of eco-friendly dyeing agents and methods. Natural dyes, derived from plant sources, are gaining traction as brands seek to reduce their environmental impact. Innovations in biotechnological processes also contribute to this trend, with techniques that enhance the uptake of dyes and reduce water consumption. Furthermore, closed-loop systems are being implemented, where the water used in the dyeing process is treated and reused, significantly cutting down on freshwater consumption and wastewater generation. This commitment to sustainable practices not only benefits the environment but also meets the growing consumer demand for eco-conscious products, ultimately leading to a more responsible textile industry.

Sustainable Practices in Dyeing for Environmental Considerations

Sustainable practices in dyeing are increasingly recognized as crucial to mitigate the environmental impact of the textile industry, which is responsible for a significant amount of pollution and resource depletion. According to a report from the World Bank, the textile sector contributes to about 20% of global water pollution, primarily due to the hazardous chemicals used in dyeing processes. Transitioning to eco-friendly dyes and methods can substantially reduce this footprint.  Natural dyes, derived from plants and minerals, not only lower toxicity levels but also minimize water usage by utilizing less water-intensive techniques, potentially reducing water consumption by up to 50%.

Natural dyes, derived from plants and minerals, not only lower toxicity levels but also minimize water usage by utilizing less water-intensive techniques, potentially reducing water consumption by up to 50%.

Furthermore, implementing efficient dyeing technologies such as digital printing and supercritical CO2 dyeing can drastically enhance sustainability. A study by the Ellen MacArthur Foundation highlights that adopting digital dyeing methods can reduce dye waste by approximately 80%, leading to more efficient utilization of resources. Additionally, supercritical CO2 dyeing eliminates the need for water altogether, showcasing a viable alternative that aligns with sustainable objectives. By prioritizing these practices, the textile industry can significantly lessen its environmental impact while still achieving vibrant, high-quality products.

Related Posts

-

Top 10 Insights into the Textile Dyeing Process You Need to Know

-

Best Spray for Textile Protection and Stain Resistance in 2023

-

Why is the Dyeing Process Essential in the Textile Industry for Quality and Sustainability

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

How to Achieve Sustainability in the Textile Industry for a Greener Future

-

How to Achieve Sustainability in the Textile Industry: Key Strategies and Practices