2026 How to Master the Dyeing Finishing Process for Textiles?

The dyeing finishing process is a critical step in textile production. Mastering this process can significantly enhance fabric quality. Industry expert Dr. Jane Smith once stated, "The success of any textile lies in its dyeing finishing." Her insights underscore the importance of precision and creativity in this field.

Understanding the dyeing finishing process requires attention to detail. Each step influences the final product's look and feel. Factors like temperature, timing, and chemical balance need careful consideration. This complexity can be daunting, yet it opens avenues for innovation. Textile professionals must stay informed about evolving techniques and sustainability practices. Mistakes in this process can lead to poor results and wasted resources.

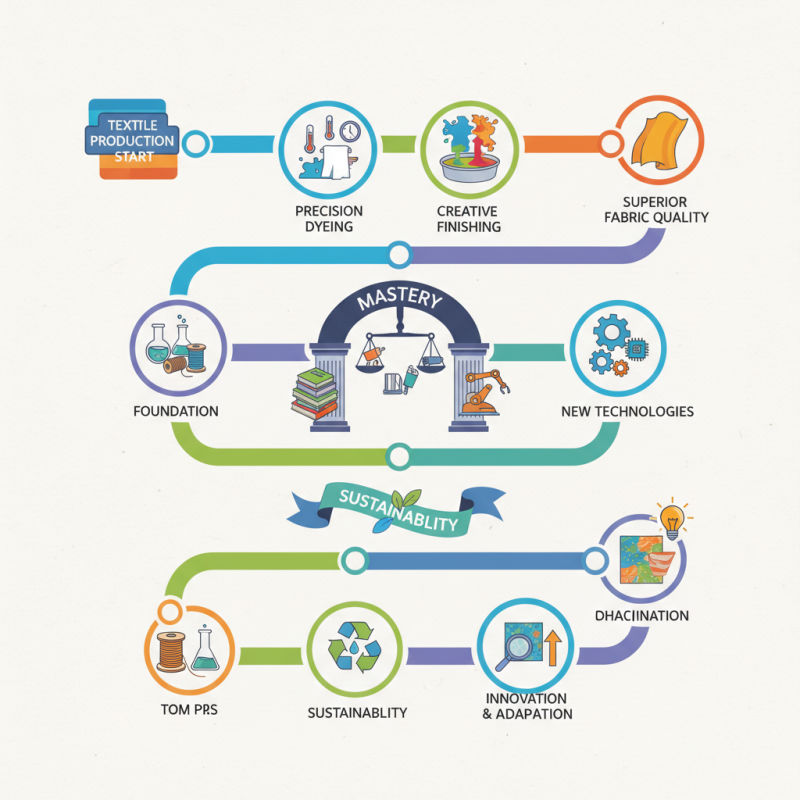

There's room for improvement in how the dyeing finishing process is approached. Sometimes, traditional methods overshadow new technologies. Some may resist change, fearing it will affect quality. Reflecting on past experiences can pave the way for better practices. Embracing a balance of old and new approaches may enhance outcomes. The journey to perfecting the dyeing finishing process is ongoing, compelling us to learn and adapt continuously.

Understanding the Basics of the Dyeing Finishing Process in Textiles

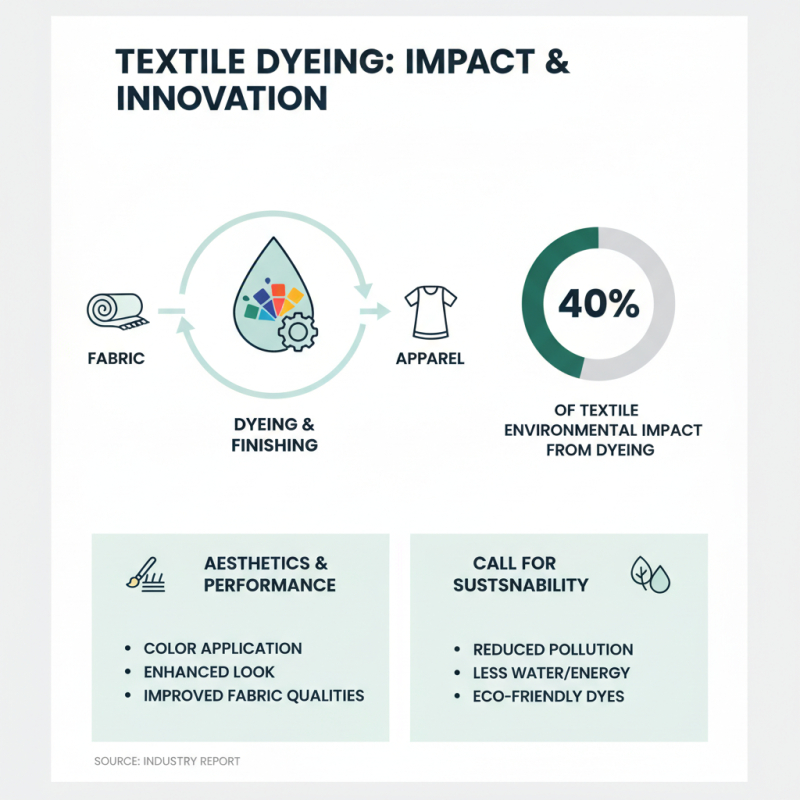

The dyeing finishing process is crucial in textile manufacturing. It involves applying color technology to fabric, enhancing both aesthetics and fabric performance. According to a recent industry report, nearly 40% of the environmental impact from textile production arises during dyeing. This highlights the need for sustainable practices.

The basics of this process include preparing, dyeing, and finishing textiles. Preparation often involves cleaning and pre-treating the fabric, paving the way for effective dye absorption. A significant challenge is achieving uniform color distribution. Studies indicate that about 25% of dyed fabrics suffer from color inconsistencies, resulting in waste and customer dissatisfaction.

Finishing, on the other hand, is about improving the textile's properties. It can involve softening, adding water repellents, or enhancing durability. However, this step is often overlooked. Many manufacturers focus solely on dyeing, missing opportunities for better quality. In 2022, it was found that 30% of fabrics failed to meet basic quality standards due to inadequate finishing. Addressing these aspects can significantly improve product value and sustainability.

Essential Materials and Equipment for Dyeing Textiles Effectively

Dyeing textiles is both an art and a science. To master this process, understanding essential materials and equipment is crucial. The American Association of Textile Chemists and Colorists reports that 85% of textile waste comes from dyeing methods. Selecting the right materials can significantly reduce this waste.

Choosing the correct dye is a starting point. Reactive dyes and acid dyes each have unique properties. Reactive dyes bond with fibers, offering bright colors but require careful handling. Acid dyes work well on protein fibers, producing vibrant hues. Knowing the type of textile you’re dyeing is key.

**Tips:** Always conduct a small test. This helps you avoid unexpected results. Remember, not every dye is compatible with every fiber. A fabric’s content needs to be clear.

Equipment is just as vital. A dyeing machine or a simple pot can work, but temperature control is critical. Infrared thermometers can help. However, not all results will meet expectations. Mistakes happen; understanding these bumps can lead to better future batches.

**Tips:** Document every step. This builds a reliable reference for future projects. Analyzing what went wrong can be just as informative as celebrating a success.

Step-by-Step Guide to Preparing Fabrics for Dyeing

Preparing fabrics for dyeing is crucial for achieving vibrant and long-lasting colors. Start with a thorough assessment of the fabric type. Different materials require specific pre-treatment. For cotton, washing with mild detergent removes impurities. For synthetic fabrics, a gentle soak in warm water is often helpful.

Next, consider the fabric’s pH level. Neutralizing the fabric can boost dye fixation. You can use a simple vinegar solution for this step. However, this method has its limitations. Some fabrics may react negatively. It's essential to test a small patch first.

After pH adjustment, rinse the fabric well. This step is easy to overlook but crucial. Any leftover vinegar can affect dye uptake. Once rinsed, let the fabric air dry completely. Ensure a clean workspace to avoid contamination. Each detail matters in this process. Skipping steps or rushing can lead to uneven coloring. Reflect on your methods. Are there areas for improvement? Take note, as mastery comes with practice and observation.

Techniques for Achieving Even Color Distribution in Dyeing

Achieving even color distribution in dyeing textiles requires careful attention to technique.

Start with proper fabric preparation. Washing fabric removes oils and dirt, allowing dye to penetrate evenly.

A well-prepared fabric can significantly enhance the final color outcome.

The dyeing process itself is critical. Use the right dyeing method for the fabric type. Immerse fabric fully in the dye bath to avoid streaks.

Ensure the dye is mixed well. Inadequate mixing often leads to uneven coloration.

Monitor the temperature closely; fluctuating temperatures can cause dye to settle unevenly.

Rinsing is another crucial step. Proper rinsing removes excess dye that can lead to blotchy appearances.

Use cold water for rinsing to set the dye and reduce bleeding.

Test samples before full-scale dyeing to evaluate color uniformity.

Mistakes in this phase can lead to disappointment, prompting reflection on techniques used.

Troubleshooting Common Issues in the Dyeing Finishing Process

Dyeing textiles is a complex process. Various issues can occur during finishing. One common problem is uneven color. This can happen due to inconsistent dye application. Make sure to check your dyeing equipment regularly. Poor equipment maintenance can lead to significant color variations.

Another challenge is the presence of stains. Stains can arise from improper handling or old equipment. To prevent this, always clean your materials before starting the dyeing process. Inspect your fabric for any existing marks. If you spot them, they might affect the final look.

Lastly, consider the water quality you use. Hard water may alter the dye's efficacy. Use water that's free from impurities. If the color doesn’t adhere properly, it might indicate a problem with the dye or the fabric. Always test your dye samples first. Embrace these challenges to refine your process.

2026 How to Master the Dyeing Finishing Process for Textiles? - Troubleshooting Common Issues in the Dyeing Finishing Process

| Issue | Description | Possible Causes | Solutions |

|---|---|---|---|

| Color Bleeding | Transfer of dye from one area to another. | Improper fixation of dye; high temperature. | Use fixing agents; control temperature during dyeing. |

| Uneven Color | Variability in shade across the fabric. | Inconsistent dye bath; fabric tension issues. | Ensure homogeneous dye bath; adjust fabric tension. |

| Fading | Loss of color intensity over time. | Ultraviolet light exposure; wash instructions not followed. | Use UV-protective finishes; provide clear care instructions. |

| Pilling | Formation of small balls of fiber on the surface. | Friction during use; low-quality fibers. | Use higher quality materials; adjust washing techniques. |

| Water Spots | Visible spots caused by mineral deposits in water. | Hard water used for dyeing. | Use distilled water; treat hard water before use. |

Related Posts

-

Why is the Dyeing Process Essential in the Textile Industry for Quality and Sustainability

-

Understanding the dyeing process for the top fabrics of 2025

-

How to Optimize the Textile Industry Dyeing Process for Better Results

-

How to Optimize the Dyeing Process in the Textile Industry for Better Results

-

Best Spray for Textile Protection and Stain Resistance in 2023

-

2025 How to Master the Textile Finishing Process for Optimal Results