2025 How to Master the Textile Finishing Process for Optimal Results

The textile finishing process plays a crucial role in determining the quality and performance of fabrics. As the final stage in textile manufacturing, it encompasses a wide range of treatments that enhance the fabric's appearance, feel, and durability. Understanding the intricacies of the textile finishing process is essential for manufacturers aiming to achieve optimal results and meet consumer demands for high-quality textiles.

In this guide, we will explore the various techniques and innovations that define the textile finishing process, focusing on how they can be effectively implemented to improve fabric characteristics. From chemical treatments to mechanical processes, mastering these methods will not only elevate the aesthetic appeal of textiles but also enhance their functional properties. As we dive into the nuances of textile finishing, readers will gain valuable insights into sustainable practices and advancements in technology that can further optimize outcomes in their textile production.

Understanding Textile Finishing: Key Concepts and Terminology

The textile finishing process plays a crucial role in determining the final characteristics of fabric, influencing its look, feel, and performance. Understanding key concepts and terminology related to finishing is essential for anyone involved in the textile industry. Finishing refers to the various treatments applied to fabrics after weaving or knitting, aimed at enhancing qualities such as appearance, hand (the way the fabric feels), durability, and functionality.

Key terms in textile finishing include "dyeing," which is the process of imparting color to textiles using various techniques and materials. Another important aspect is "finishing agents," which are chemicals or compounds applied to achieve desired properties like water resistance, wrinkle reduction, or flame retardancy.

Additionally, "mechanical finishing" involves physical methods such as calendering or brushing that alter the fabric's surface texture. Understanding these concepts enables professionals to select appropriate finishing methods, ensuring the fabric meets specific performance requirements and aesthetic goals.

Essential Steps in the Textile Finishing Process

The textile finishing process plays a crucial role in determining the final quality and performance of fabric. To achieve optimal results, several essential steps must be meticulously followed. The first step involves pre-treatment, where fabrics are cleaned and prepared for subsequent processes. This generally includes removing impurities, sizing agents, and any residual chemicals from the manufacturing phase. Proper pre-treatment sets the foundation for the finishing treatments, ensuring that the fabric can absorb finishes uniformly.

Following pre-treatment, the next critical stage is the application of finishes, which can include chemical treatments, coating applications, and mechanical processes. Depending on the desired outcome, finishes such as softening agents, stain repellents, or anti-wrinkle treatments are applied to enhance the fabric's properties. It is essential to carefully calibrate the method of application, whether it's padding, spraying, or dipping, to ensure even coverage and effectiveness. Finally, curing or drying is performed to set the finishes, allowing the treated fabric to maintain its enhanced characteristics during use. By adhering to these core steps in the textile finishing process, manufacturers can significantly improve the efficacy and quality of their final products.

Textile Finishing Process: Key Steps and Their Importance

Common Techniques for Effective Textile Finishing

Textile finishing is an essential stage in the fabric production process, significantly influencing the final fabric's aesthetic appeal, durability, and functionality. Among the common techniques used in textile finishing, processes such as bleaching, dyeing, and coating are critical. According to the latest industry report from Technavio, the global textile finishing market is projected to grow by over 5% annually, driven by the increasing demand for functional and sustainable fabrics.

Bleaching, often the first step in the finishing process, is primarily aimed at removing impurities from fabrics to enhance brightness and uniformity. The use of environmentally friendly bleaching agents has surged, illustrating a growing trend towards sustainable practices in textile manufacturing. Similarly, dyeing techniques have evolved from traditional methods to include innovative approaches like digital printing and eco-friendly dyes, contributing to higher efficiency and reduced water consumption—an area highlighted in a report by the International Council of Textile Manufacturers, which notes that modern dyeing technologies can save up to 50% more water compared to conventional methods.

Coating is another crucial finishing technique, enhancing the fabric's properties by providing waterproofing, stain resistance, or flame retardancy. Studies suggest that the global demand for coated fabrics is anticipated to rise, reflecting the increasing need for specialized textiles in industries such as automotive and architecture. In fact, projected growth in this sector is estimated to reach $30 billion by 2025, as mentioned in a recent analysis by Market Research Future. These advancements in textile finishing techniques not only improve the functional characteristics of fabrics but also align with the broader shift towards sustainability and innovation within the textile industry.

2025 How to Master the Textile Finishing Process for Optimal Results - Common Techniques for Effective Textile Finishing

| Technique | Description | Benefits | Common Applications |

|---|---|---|---|

| Mercerization | A chemical treatment that improves dye uptake and adds luster to cotton fabrics. | Enhances durability and vibrancy of colors. | Cotton shirts, denim, and home textiles. |

| Calendering | Pressing fabric between rollers to achieve smoothness and sheen. | Increases shine and minimizes wrinkles. | Dress fabrics, cottons, and synthetic textiles. |

| Chemical Finishing | Application of chemical agents to impart special properties to textiles. | Adds features like water repellency and flame retardance. | Outdoor gear, upholstery, and industrial textile applications. |

| Dyeing | The process of adding color to textile fabrics through various methods. | Achieves a wide range of colors and patterns. | Fashion apparel, home décor, and technical textiles. |

| Finishing with Heat | Using heat to set dyes, remove wrinkles, and improve fabric drape. | Promotes long-lasting performance and aesthetic appeal. | Woven fabrics, garments, and specialty textiles. |

Quality Control Measures in Textile Finishing

In the textile industry, ensuring quality in the finishing process is crucial for delivering superior products. Effective quality control measures play a significant role in enhancing the overall efficiency of textile finishing. According to a report by the Textile Institute, approximately 30% of defects in finished textiles arise during the finishing stages. This highlights the necessity for rigorous quality checks to monitor various parameters such as dye consistency, fabric weight, and surface quality, which can significantly impact the final product's marketability.

Implementing systematic quality control protocols can reduce waste and rework, leading to cost savings and improved productivity. Tools such as Statistical Process Control (SPC) have become essential in the finishing process. By applying SPC, manufacturers can statistically analyze data to identify deviations from set standards. A study conducted by the International Textile and Apparel Association indicated that companies utilizing SPC in their finishing processes reported a 20% reduction in defect rates. Furthermore, regular inspections and testing for colorfastness and shrinkage compliance ensure that finished textiles meet consumer expectations and regulatory standards. Adopting these measures not only ensures compliance with industry standards but also builds trust with clients and end-users, positioning manufacturers competitively in the evolving textile market.

Future Trends in Textile Finishing Technologies

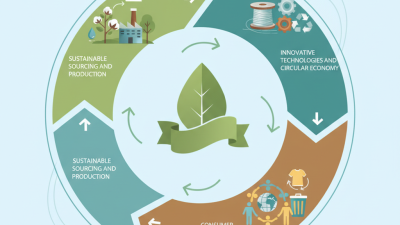

As we look towards 2025, the textile finishing process is poised for significant advancements, emphasizing sustainability and efficiency. One major trend is the integration of eco-friendly materials and processes, which aim to minimize environmental impact while maintaining high-quality results. Innovations such as waterless dyeing technologies and biodegradable finishes are being developed to reduce wastewater discharge and chemical usage. This shift not only responds to consumer demand for sustainable products but also aligns with global regulations aimed at curbing pollution in the textile industry.

Another compelling trend in textile finishing technologies is the incorporation of smart textiles, which are increasingly designed to respond dynamically to environmental stimuli. For instance, fabrics with embedded sensors can adjust their properties, such as breathability or insulation, based on external conditions, thus enhancing user experience. Furthermore, there is a growing interest in automation and AI-driven processes that optimize production workflows, reduce lead times, and improve consistency in finishing results. These advancements point towards a future where textile finishing is not only smarter but also more attuned to the needs of consumers and the environment alike.