2026 How to Use Spray for Textile Effectively in Your Projects?

As we explore the use of spray for textile, it's crucial to understand its potential and limitations. This method has gained popularity in various projects, from fashion to home decor. Many artists and designers favor spray for textile due to its versatility and ease of use. However, not every application yields perfect results, which invites reflection on techniques and approaches.

Using spray for textile requires practice and skill. Beginners may face challenges, such as uneven coverage or over-saturation. It's essential to test different spray techniques on sample fabrics. This experimentation helps in finding the right pressure and distance for effective application. Colors can appear differently when sprayed, so pre-testing is vital.

The impact of spray on textile is significant yet imperfect. Some users find that certain fabrics absorb spray unevenly. Others struggle with cleanup and overspray issues. These setbacks should be seen as learning opportunities. Embrace the process, and don't shy away from making mistakes. Remember, creativity often comes from unexpected outcomes.

Understanding the Basics of Textile Sprays and Their Applications

When working with textile sprays, understanding the basics is crucial. Textile sprays are versatile, used for everything from fabric painting to creating unique patterns. According to a recent industry report, the textile spray market is projected to grow by 5.2% annually. This suggests increased interest and demand among crafters and professionals alike.

Different types of textile sprays cater to various applications. For example, dye sprays are ideal for achieving vibrant colors while maintaining fabric integrity. In contrast, coating sprays enhance durability and weather resistance. Knowing the right spray for your project significantly impacts the final result.

**Tips:** Always test your spray on a scrap piece first. This helps avoid unexpected outcomes. Spray from a distance of 6-12 inches. This ensures even coverage. Clean your nozzle regularly to prevent clogs.

While sprays can achieve stunning effects, improper use can lead to disappointment. Inconsistent application might result in splotches or uneven colors. It's essential to be mindful of the amount you apply. Sometimes, less is more when achieving the desired aesthetic. Remember, practice makes perfect in mastering the use of textile sprays.

2026 Textile Spray Usage Statistics

Choosing the Right Spray for Your Textile Project Needs

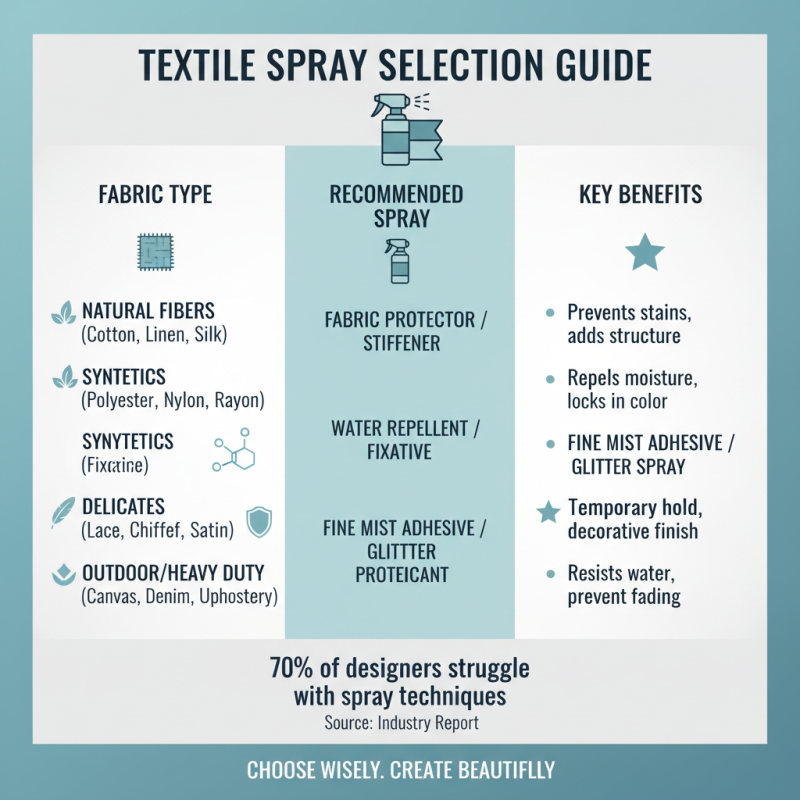

Choosing the right spray for your textile projects is essential. Different fabrics require different types of sprays, and the effects can vary widely. According to a recent industry report, nearly 70% of textile designers struggle with spray application techniques. This highlights the need for proper guidance in selecting the right product.

Consider the type of fabric you are working with. Natural fibers often absorb sprays differently compared to synthetic materials. For instance, cotton may require a water-based spray to avoid overwhelming the fabric, while polyester could work better with a solvent-based option. Understanding absorption rates is crucial. Research indicates that using the wrong spray can lead to undesirable effects, such as faded colors or uneven textures.

Another common challenge is achieving precision during application. Many users report issues with spray nozzles clogging or uneven distribution. This can lead to a patchy finish that detracts from the overall project. Experimenting with various nozzles and distances while spraying can yield better results. Each project may require several attempts to perfect the technique, so be prepared for trial and error. A reflective approach often leads to improved outcomes in future applications.

Techniques for Applying Spray on Different Fabric Types

When applying spray to various fabric types, preparation is key. Start with clean, dry fabrics. Proteins like silk absorb differently than cotton. A light mist may work for silk, while thicker fabrics can require more product. It’s essential to test on a small area first. Sometimes, the results are unexpected. Splatter or uneven patches can happen, but they might add character to your project.

Consider the technique as well. Use a sweeping motion for even coverage. Quick bursts are ideal for lighter fabrics. Heavier fabrics may need a more gradual approach. Maintaining a consistent distance from the fabric is crucial. Too close can lead to dripping; too far can create a weak bond. Mistakes can be an opportunity for creativity. A design you didn't intend can turn out beautifully. Embrace the imperfections for unique results.

2026 How to Use Spray for Textile Effectively in Your Projects? - Techniques for Applying Spray on Different Fabric Types

| Fabric Type | Recommended Spray Texture | Application Technique | Drying Time | Tips |

|---|---|---|---|---|

| Cotton | Matte Finish | Light Mist Application | 30 minutes | Use a heat source for faster drying. |

| Silk | Glossy Finish | Even Layer Application | 1 hour | Avoid over-saturating to prevent discoloration. |

| Denim | Distressed Look | Spot Application | 45 minutes | Test on a sample piece first. |

| Polyester | Satin Finish | Crosshatch Technique | 20 minutes | Ensure the fabric is securely held. |

Tips for Ensuring Even Coverage and Preventing Overspray

Achieving an even coverage when using spray for textiles is crucial for professional results. According to a recent industry report, about 30% of users experience issues with overspray. This leads to wasted materials and uneven finishes. To combat this, it’s essential to keep the spray nozzle at a consistent distance from the surface. A range of 10 to 12 inches is ideal, as it minimizes the risk of build-up.

Another common mistake is not considering wind conditions. For outdoor projects, wind can shift the spray direction, causing overspray on unintended areas. The report highlights that outdoor users face a higher percentage of overspray incidents, at nearly 50%. Using a spray shield can help control the spray pattern and protect areas you want to keep untouched. Additionally, adjusting the spray pattern width can create more control. A narrower spray is often better for detailed work.

It’s important to practice on scrap fabric before starting a project. This allows for adjustments to the pressure and angle of the spray. Users often overlook this step, leading to frustration during application. Experimenting with settings ensures that your final application is smooth and even. If issues arise, reflecting on your technique is essential. Small tweaks can make a significant difference, and learning from previous mistakes can enhance future results.

Post-Application Care and Maintenance for Sprayed Textiles

Post-application care is vital for maintaining the beauty of sprayed textiles. After applying the spray, allow the fabric to cure properly. This step can take from a few hours to a couple of days, depending on the spray's composition. Avoid rushing this process. Rushing might lead to uneven finishes or peeling.

Once cured, gentle cleaning is essential. Use a soft brush or cloth to remove dirt. For tougher stains, a mild detergent can be applied. Test any cleaning solution on a small area first. Sometimes, what seems like a harmless product can damage the surface. Patience is key, as aggressive scrubbing can lift the finish.

Regular maintenance helps prolong the life of the sprayed textile. Store items in a cool, dry place. Avoid direct sunlight, which can fade colors over time. Assess the condition of the textile periodically. Identify signs of wear early. Instructions might not cover every scenario, and experience often teaches us where to be cautious. Embracing imperfections and learning from them is part of the journey in caring for sprayed textiles.

Related Posts

-

Best Spray for Textile Protection and Stain Resistance in 2023

-

How to Navigate the Dyeing Finishing Process for Optimal Fabric Results

-

How to Achieve Sustainability in the Textile Industry: Key Strategies and Practices

-

How to Optimize the Dyeing Process in the Textile Industry for Better Results

-

How to Optimize the Textile Industry Dyeing Process for Better Results

-

10 Essential Tips for Achieving Sustainability in the Textile Industry