10 Essential Tips for Using Textile Spray Effectively?

Textile spray has revolutionized the fabric care industry. According to a recent report by Research and Markets, the global textile chemicals market is expected to grow significantly, driven by innovations like textile spray. This product allows users to refresh fabrics efficiently, making it a favorite among households and businesses alike.

Perfect application often requires careful consideration. Many users may overlook vital details, like proper distance and surface preparation. Industry experts suggest that improper usage can lead to uneven coatings and reduced longevity of the fabric protection. Additionally, a survey from Statista indicates that 45% of users are unaware of the recommended techniques for optimal results with textile spray.

It's essential to recognize that effective use can vary significantly across different fabrics. Some textiles may react poorly to certain sprays, leading to dissatisfaction. Understanding specific needs for each type of fabric is crucial. Awareness of these factors can lead to better outcomes and more effective fabric care solutions. Adopting these tips can make a noticeable difference in your textile maintenance routine.

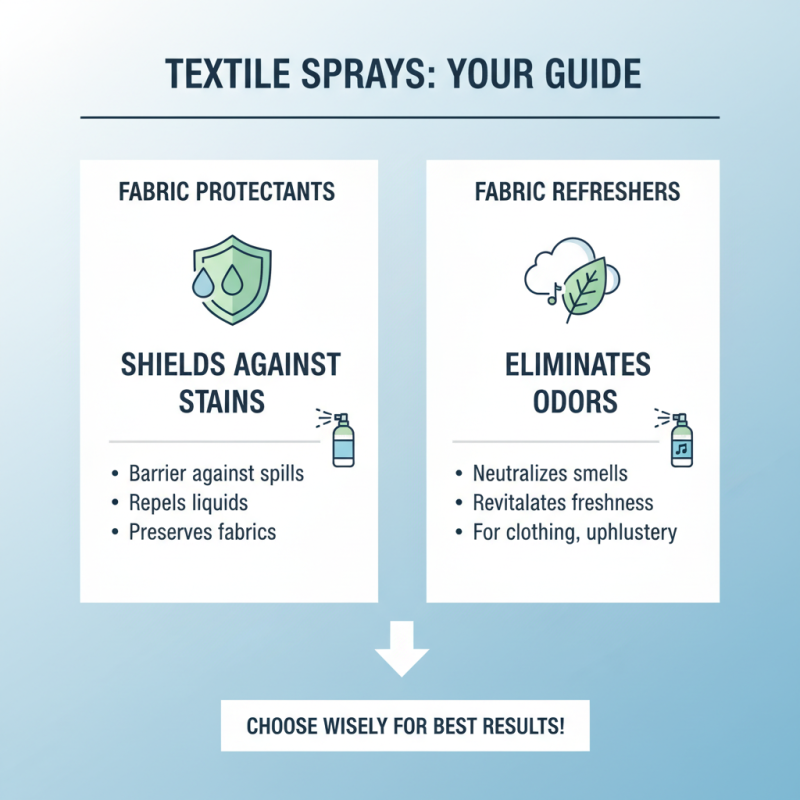

Understanding Textile Spray Types and Their Applications

When exploring textile sprays, it’s essential to understand the different types available. There are fabric protectants, which create a barrier against stains and spills. Then there are fabric refreshers designed to eliminate odors. Each spray serves distinct purposes, and knowing this can maximize your results.

When using textile sprays, preparation is key. Always test a small, inconspicuous area first. This helps avoid any surprises later. Remember, spray in light, even coats. Too much can lead to a sticky residue. It’s sometimes a challenge to find the right distance for application. Practice makes perfect, after all.

Another tips to consider is the drying time. Ensure that fibers dry completely before use. Damp fabrics can attract dirt quickly, leading to more work later. Reflect on your application technique regularly. Are you using enough or too much product? This can affect not only effectiveness but also the longevity of the fabric's appearance.

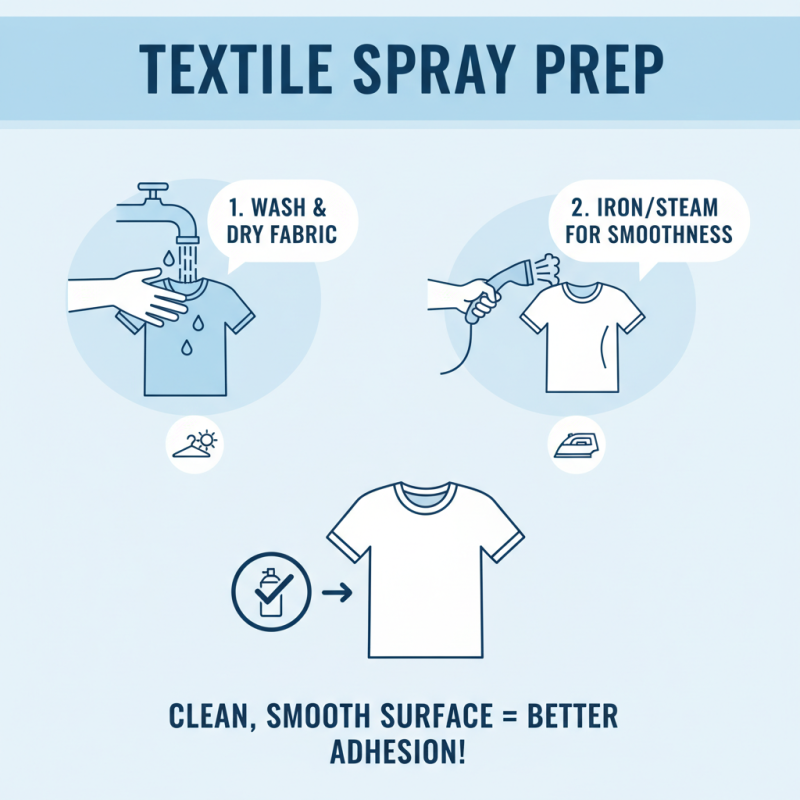

Preparing the Fabric Surface Before Using Textile Spray

Preparing the fabric surface is crucial before using textile spray. If the fabric is dirty, the spray won't adhere well. Begin by washing the item to remove any dust or oil. Allow it to dry completely. If the fabric is wrinkled, steam or iron it carefully. A smooth surface enhances the final outcome.

Next, consider the type of fabric you're working with. Some fabrics can absorb sprays differently. Test a small area first to ensure compatibility. This step prevents unnecessary disappointment. If the fabric reacts poorly, you may need to reconsider your choice. Remember that perfect results don’t always happen on the first try. Mistakes are a part of the process.

Finally, don’t rush the preparation phase. Take your time to ensure everything is ready. Apply the spray in even strokes. Avoid clumping or oversaturating the fabric. This care will lead to a more polished result. Be ready to adapt and learn as you go. Every project provides valuable lessons.

Techniques for Even Application of Textile Spray

When applying textile spray, even application is crucial for the best results. Research shows that uneven spraying can lead to patchy finishes and wasted product, with up to 30% of spray being absorbed or poorly distributed. Begin by preparing your textile surface. Clean it thoroughly to remove dirt and oils that may repel the spray.

Use a sweeping motion while spraying. This technique helps achieve a uniform coat across the surface. Holding the can about 6 to 12 inches away allows for better coverage. If you notice any drips or pools forming, you may be applying too much at once. Mistakes happen; adjusting your distance can resolve many issues.

Be aware of environmental conditions too. High humidity or windy conditions can affect drying time and application quality. Aim for a calm day, ideally between 65°F and 85°F for optimal results. Even with the best techniques, some fabric types may absorb spray differently. Testing on a small area can reveal how the textile reacts. Aim for consistency, but be ready to adjust methods as needed.

Curing and Drying Time: Best Practices for Optimal Results

Curing and drying times are crucial for achieving the best results with textile spray. To start, ensure your workspace is well-ventilated. Airflow helps speed up the drying process. Choose a dry, warm day for optimal curing. The temperature affects how quickly the spray adheres and sets. You might be tempted to rush this step. However, impatience can lead to uneven coverage or peeling.

Allow the spray to dry completely before using or washing your item. Typically, this can take several hours. It’s essential to refer to the spray's instructions for specific timing. A common mistake is not waiting long enough. Skipping this can ruin your project. Consider testing on scrap fabric to gauge drying times.

After the initial drying period, allow additional curing time. This ensures that the color sets well into the fibers. Sometimes, even when the surface feels dry, the interior may still need more time. If you notice fading or smudging, reflect on your drying process. Adjust your environment to improve results. Dedicating time to proper curing can be the difference between success and disappointment.

10 Essential Tips for Using Textile Spray Effectively

The following bar chart illustrates the optimal curing and drying times for various fabric types when using textile spray. This data can help you achieve the best results in your textile projects.

Safety Precautions When Using Textile Spray Products

When using textile spray products, safety is paramount. According to a report from the American Textile Manufacturers Institute, improper use can lead to inhalation issues and skin irritations. Always work in a well-ventilated area. This helps to reduce vapor accumulation, which can be harmful. Wear a mask and gloves to further protect yourself.

Be mindful of flammability. Many textile sprays contain solvents that can ignite easily. Keep sprays away from open flames or high heat. Test the product on a small area first. This prevents possible discoloration on your fabrics. The industry average indicates that nearly 15% of users experience unexpected reactions due to lack of testing.

Consider storage as well. Store sprays in cool, dry places. A study found that most accidents occur due to improper storage practices. Keep them out of reach of children. Avoid leaving cans in vehicles, as temperature changes can increase pressure. Remember, safety isn’t just about following rules but creating good habits.

10 Essential Tips for Using Textile Spray Effectively

| Tip | Description | Safety Precaution |

|---|---|---|

| 1. Read Labels | Always read the product label for instructions and warnings. | Use in well-ventilated areas. |

| 2. Test on Fabric | Test on a small, inconspicuous area of the fabric first. | Wear gloves to avoid skin contact. |

| 3. Hold Proper Distance | Keep the spray nozzle about 6-12 inches from the fabric. | Avoid inhaling fumes. |

| 4. Use Even Strokes | Apply the spray in even, sweeping motions. | Do not spray on face or near eyes. |

| 5. Allow Proper Drying Time | Let the fabric dry completely before use. | Store product in a cool, dry place. |

| 6. Avoid Direct Sunlight | Do not expose treated fabric to direct sunlight immediately after application. | Protect from heat sources. |

| 7. Check for Stains | Look for any discoloration before use. | Keep away from children's reach. |

| 8. Clean Nozzle After Use | Clean the nozzle to prevent clogs. | Do not use near open flames. |

| 9. Follow Storage Guidelines | Store product upright and according to label instructions. | Avoid extreme temperature changes. |

| 10. Dispose of Properly | Dispose of empty cans according to local regulations. | Do not puncture or incinerate cans. |

Related Posts

-

2026 How to Use Spray for Textile Effectively in Your Projects?

-

2026 How to Master the Dyeing Finishing Process for Textiles?

-

Top 10 Insights into the Textile Dyeing Process You Need to Know

-

How to Optimize the Textile Industry Dyeing Process for Better Results

-

How to Achieve Sustainability in the Textile Industry for a Greener Future

-

10 Essential Tips for Achieving Sustainability in the Textile Industry