10 Essential Tips for Achieving Sustainability in the Textile Industry

The textile industry and sustainability have become critical points of discussion as the world seeks to mitigate environmental harm and promote ethical practices. As one of the largest contributors to pollution and waste, the textile sector faces immense pressure to evolve and implement sustainable practices. In light of growing consumer awareness and demand for eco-friendly products, professionals within the industry are exploring innovative solutions to shift towards more responsible production methods.

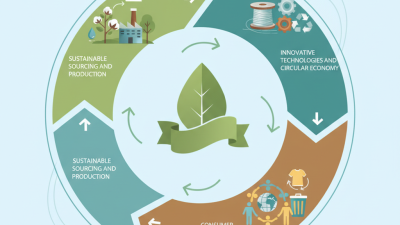

Achieving sustainability in the textile industry requires a multifaceted approach that addresses the entire supply chain—from raw material sourcing to manufacturing processes and consumer use. Recognizing the interdependencies within this system allows stakeholders to make more informed decisions that not only benefit their organizations but also contribute positively to the environment and society at large. In this discourse, we will explore ten essential tips that can guide industry players in their pursuit of sustainability, highlighting practical strategies and innovative practices that lead to a greener future for textiles. By embracing these recommendations, the textile industry can play a pivotal role in fostering a sustainable economy and ensuring the health of our planet for generations to come.

Understanding Sustainability in the Textile Industry

Understanding sustainability in the textile industry requires a comprehensive approach that considers both environmental and social impacts. The textile industry is one of the most resource-intensive sectors, often associated with pollution, waste, and unethical labor practices. Achieving sustainability involves employing eco-friendly materials, reducing water consumption, and ensuring fair labor practices throughout the supply chain. By prioritizing sustainability, the industry can not only minimize its ecological footprint but also cater to the growing consumer demand for ethical products.

To effectively implement sustainable practices, companies can follow essential tips. First, sourcing organic and recycled materials can significantly reduce environmental impact. Opting for fabrics made from organic cotton, hemp, or recycled polyester decreases reliance on virgin resources and lowers pollution levels. Second, adopting efficient manufacturing processes can help conserve energy and water. Investing in innovative technologies and practices, such as waterless dyeing techniques, can lead to substantial savings in both resources and costs.

Another critical aspect of sustainability is adopting a circular economy model. This means designing products with their end-of-life in mind, promoting recycling and upcycling, and encouraging customers to return used textiles. By implementing take-back programs, brands can reduce landfill waste and create a closed-loop system where materials are reused and repurposed. Ultimately, understanding and embracing these sustainable practices can pave the way for a more responsible and resilient textile industry.

10 Essential Tips for Achieving Sustainability in the Textile Industry

| Tip | Description | Importance | Implementation Challenge |

|---|---|---|---|

| Use Sustainable Materials | Incorporating organic, recycled, or biodegradable fabrics. | Reduces environmental impact. | Higher cost and sourcing difficulties. |

| Implement Energy Efficiency | Using energy-efficient machinery and practices. | Lowers emissions and costs. | Initial investment in equipment. |

| Reduce Water Usage | Adopting water-saving technologies. | Protects water resources. | Operational adjustments required. |

| Supply Chain Transparency | Tracking materials from source to product. | Builds consumer trust. | Complex tracking processes. |

| Implement Recycling Programs | Creating systems for recycling fabric waste. | Reduces landfill waste. | Logistical challenges. |

| Educate Consumers | Raising awareness of sustainable practices. | Encourages responsible consumption. | Requires resources for outreach. |

| Invest in Research | Developing sustainable technologies. | Promotes innovation. | Funding and time commitments. |

| Collaboration | Partnering with other eco-conscious companies. | Multiplies resources and impact. | Finding compatible partners. |

| Sustainable Packaging | Using compostable or recyclable packaging materials. | Minimizes waste. | Availability and cost of materials. |

| Lifecycle Assessment | Evaluating environmental impacts of products. | Identifies areas for improvement. | Data collection and analysis efforts. |

Evaluating Environmental Impact of Textile Production

The textile industry is one of the largest contributors to environmental degradation, with an estimated 1.2 billion tons of CO2 emissions produced annually, according to the Global Fashion Agenda. Evaluating the environmental impact of textile production involves examining the entire lifecycle of textiles, from raw material sourcing to manufacturing processes, and ultimately, product disposal. The use of non-renewable resources, excessive water consumption, and harmful chemical usage are critical factors that exacerbate this impact. For instance, producing just a single pair of jeans requires approximately 7,500 liters of water, illustrating the industry's significant water footprint.

Furthermore, the production phase often entails the release of toxins and pollutants into the environment. A report by the World Resources Institute states that textile dyeing and finishing processes are responsible for discharging around 20% of the world's clean water pollution. As consumers increasingly demand transparency and sustainability, textile manufacturers must assess their environmental practices rigorously. Implementing strategies such as closed-loop systems, which recycle water and chemicals, and transitioning to eco-friendly materials can substantially reduce the industry's carbon footprint. By adopting such measures, the textile sector can mitigate its environmental impact and move towards a more sustainable future.

Implementing Sustainable Material Sourcing Practices

Implementing sustainable material sourcing practices is a cornerstone for achieving sustainability in the textile industry. According to a report from the Ellen MacArthur Foundation, the fashion industry accounts for 10% of global carbon emissions, and this figure could be drastically reduced through smarter sourcing strategies. By opting for organic cotton, recycled polyester, or innovative fabrics like Tencel, companies can minimize their environmental impact and support circular economy practices.

One essential tip for sustainable material sourcing is to prioritize certification. Materials sourced from certified suppliers ensure adherence to environmental and social standards, which can significantly enhance transparency in the supply chain. Furthermore, selecting suppliers that practice ethical labor and sustainable agriculture not only fosters professionalism but also builds consumer trust. The Global Fashion Agenda emphasizes that addressing sourcing choices is imperative as nearly 70% of a brand’s total emissions come from their supply chain.

Another effective strategy is to engage in collaborative sourcing. By partnering with other brands and suppliers committed to sustainability, firms can share knowledge, resources, and technological innovations. This can lead to the development of a more resilient and eco-friendly supply chain. For instance, adopting a closed-loop system where materials are reused and recycled can significantly reduce waste. Research indicates that moving towards such initiatives can cut textile waste by up to 50%, showcasing the immense potential for sustainability in our industry.

Promoting Ethical Labor Practices in Textile Manufacturing

Promoting ethical labor practices in the textile manufacturing sector is crucial for fostering sustainability and social responsibility. One of the primary steps in achieving this is ensuring fair wages for all workers. Many garment workers are often paid well below a living wage, making it essential for manufacturers to analyze their pay structures and commit to compensating employees fairly. Implementing transparent wage policies not only empowers workers but also enhances productivity, leading to better overall results for companies.

In addition to fair wages, it is vital to promote safe working conditions. Many textile factories lack the necessary safety measures, resulting in a high risk of accidents and health issues. By adhering to international safety standards and continuously monitoring workplace conditions, manufacturers can create an environment where employees feel secure and valued. Moreover, investing in training programs that educate workers about their rights and safety practices will further enhance their well-being and encourage a culture of accountability within the industry. By prioritizing these ethical labor practices, the textile industry can move towards a more sustainable future that benefits all stakeholders involved.

Innovating Processes for Reducing Waste in Textiles

Innovating processes is crucial for reducing waste in the textile industry, which is notorious for its environmental impact. One effective approach involves embracing circular fashion principles, where textile waste is transformed into new products rather than ending up in landfills. Companies can achieve this by implementing advanced recycling technologies that break down fibers and regenerate raw materials. This not only decreases waste but also conserves resources and reduces the need for virgin materials in production.

Another innovative process is the integration of digital technologies into the production pipeline. Tools such as 3D printing and computer-aided design can streamline manufacturing, allowing for precise cuts and minimizing fabric offcuts. By adopting a just-in-time production model, manufacturers can produce garments based on real-time demand, further reducing excess inventory and waste. Additionally, leveraging smart textiles that require less water and energy during production can significantly contribute to sustainability efforts. These innovations showcase the potential for the textile industry to evolve towards a more sustainable future by placing waste reduction at the forefront of their practices.

Waste Generation in the Textile Industry

Related Posts

-

How to Achieve Sustainability in the Textile Industry for a Greener Future

-

How to Achieve Sustainability in the Textile Industry: Key Strategies and Practices

-

Top 10 Insights into the Textile Dyeing Process You Need to Know

-

Why is the Dyeing Process Essential in the Textile Industry for Quality and Sustainability

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

Best Spray for Textile Protection and Stain Resistance in 2023