Digital Transformation Best Practices in Textile Industry Process?

The textile industry process is undergoing a significant transformation. Digital transformation is reshaping how companies operate, from production to distribution. As technology advances, it’s essential to embrace these changes.

Industry players must adopt best practices to thrive. Integrating automation can boost efficiency, but it requires careful planning. Many companies face challenges in data management and integration. Poor data quality can lead to inefficiencies. Therefore, enhancing data insights is crucial for decision-making.

Collaboration across the value chain is vital. By connecting supply chains digitally, organizations can respond faster to market demands. However, resistance to change can hinder progress. A willingness to adapt is key. Embracing digital tools can revolutionize the textile industry process and provide a competitive edge.

Understanding Digital Transformation in the Textile Industry

Digital transformation is reshaping the textile industry. Companies are adopting new technologies to improve production and customer experience.

According to a report by McKinsey, digital initiatives can boost productivity by 20-30%. These changes include automation in weaving and dyeing processes.

Such shifts promise efficiency, yet challenges persist.

Many fabric manufacturers struggle with integrating digital tools. Legacy systems often impede progress. Data from PwC suggests that

70% of companies face cultural resistance to change. This is particularly evident in older firms. Employees may resist adopting new technologies.

Training is essential, but not always prioritized.

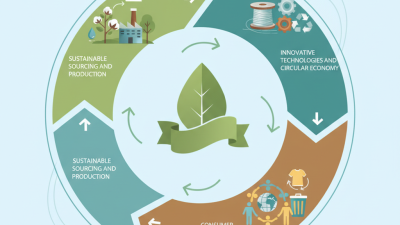

Additionally, sustainability is a growing focus in the textile sector. Digital practices can enhance traceability and reduce waste.

However, hurdles remain. Not every digital solution is effective. A study from Deloitte reveals that 60% of digital projects fail to deliver expected results.

Companies must learn from these failures to optimize their approaches. Balancing innovation with operational realities is key to success.

Key Technologies Driving Digital Transformation in Textiles

The textile industry is undergoing significant change. Key technologies are driving this digital transformation. According to a recent report, over 90% of textile companies are investing in digital technologies. These investments are primarily in automation, data analytics, and IoT, reshaping processes.

Automation enhances production efficiency. By integrating robotics, manufacturers can reduce labor costs and improve accuracy. However, the adaptation of such technology often faces resistance. Workers may fear job loss, creating a need for effective change management strategies. Additionally, while automation promises efficiency, it can lead to unforeseen complexities.

Data analytics offers deeper insights into customer preferences. Companies utilize these insights to create personalized products. Yet, many struggle with data management. Poor data quality can lead to misguided decisions and wasted resources. Moreover, IoT enables real-time monitoring of equipment and inventory. This connectivity optimizes supply chains. However, cybersecurity remains a critical concern, as interconnected systems can be vulnerable to breaches. The path to digital transformation is layered with both opportunities and challenges.

Best Practices for Implementing Digital Solutions in Textile Processes

The textile industry is evolving rapidly. Implementing digital solutions can streamline processes and enhance productivity. Data analytics, for instance, can provide insights into consumer preferences. This helps companies make informed decisions on product designs and inventory levels.

Training staff is crucial for success. Many employees may resist change. Effective communication about the benefits can mitigate this resistance. It’s important to involve them in the transition. This can foster a sense of ownership and commitment. Regular feedback sessions can reveal challenges and encourage continuous improvement.

Moreover, investing in robust cybersecurity is essential. Digital solutions create new vulnerabilities. Companies often underestimate these threats. Protecting sensitive data should be a priority. Regular assessments can identify weaknesses in security protocols. Failing to address these issues can lead to significant repercussions. Implementing digital transformation demands strategic planning and adaptability.

Measuring Success: KPIs for Digital Transformation in Textiles

Digital transformation is reshaping the textile industry. Companies are leveraging technology to improve efficiency and customer satisfaction. However, measuring the success of these transformations is crucial. Key Performance Indicators (KPIs) can provide valuable insights.

Reports indicate that 70% of digital transformation efforts fail due to unclear goals. Many companies struggle to define KPIs that align with their strategies. Effective KPIs in textiles can include production efficiency, supply chain visibility, and customer engagement rates. For instance, tracking production cycle time can reveal bottlenecks.

In some cases, companies overlook employee engagement. A 2022 study found that 40% of workers felt disconnected from digital initiatives. This gap can hinder progress. A digital transformation strategy should involve regular feedback from all stakeholders. An inclusive approach fosters a culture of innovation. Ultimately, successful digital transformation in textiles requires a balanced focus on technology, employee satisfaction, and clearly defined KPIs.

Digital Transformation Best Practices in Textile Industry Process - Measuring Success: KPIs for Digital Transformation in Textiles

| KPI | Description | Measurement Frequency | Target Value |

|---|---|---|---|

| Production Efficiency | Measures the ratio of actual output to standard output | Monthly | 90% |

| Supply Chain Cycle Time | Time taken to fulfill an order from initiation to delivery | Quarterly | 10 days |

| Return on Investment (ROI) | Financial return gained from digital investments | Annually | 15% |

| Customer Satisfaction Score | Gauge of customer satisfaction based on feedback | Monthly | 85% |

| Digital User Engagement | Measuring how users interact with digital platforms | Weekly | 75% |

Future Trends in Digital Technology for the Textile Industry

The textile industry is rapidly evolving with digital technology. Innovations are transforming traditional processes. Automation, data analytics, and smart fabrics are gaining traction. These tools enhance productivity and reduce waste. The future is bright, but challenges remain.

Tips: Embrace experimentation. Test new technologies like IoT and AI. Monitor results closely. This will help in making data-driven decisions.

Sustainability is key in future trends. Digital technologies allow for better resource management. Companies can track their environmental impact. Implementing these changes can be daunting, but the benefits are significant. The industry must adapt to meet consumer demands for green practices.

Tips: Engage your team in the transition. Training is crucial for successful adoption. Clear communication will ease the adjustment period. Digital transformation does not happen overnight. Continuous improvement is essential.

Related Posts

-

How to Optimize the Dyeing Process in the Textile Industry for Better Results

-

Best Spray for Textile Protection and Stain Resistance in 2023

-

How to Achieve Sustainability in the Textile Industry: Key Strategies and Practices

-

How to Navigate the Dyeing Finishing Process for Optimal Fabric Results

-

2025 How to Master the Textile Finishing Process for Optimal Results

-

2025 How to Master the Textile Finishing Process for Optimal Results